News Story

MATRIX Interns Overcome Setbacks and Succeed

A group of students now further understands the importance of researching solutions and asking questions in the field of engineering.

The Summer 2025 cohort of University of Maryland (UMD) MATRIX Lab interns spent the past few months tackling projects ranging from uncrewed aerial systems to ingestible capsules to underwater experiments. Each student gained valuable skills through real-world research projects and learned the importance of teamwork, patience, and problem solving.

Capsules and Collaboration

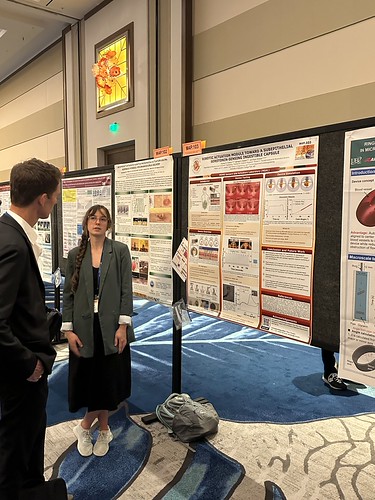

MATRIX Lab Interns Andrew (left) and Charlotte (right) discuss ingestible capsule project in the SMART Building Mechanical Engineering Lab

Andrew and Charlotte joined together to contribute to a research project currently being worked on by MATRIX Lab Director of Remote Sensing and Microsystems Dr. Justin Stine. They each helped advance the ingestible capsule – a device that measures levels of the gas H2S in the gastrointestinal tract in order to find a link between elevated levels and bowel disease. Charlotte took on microcontroller programming and device communication, while Andrew worked on smaller parts of a larger, multi-line gas collection chamber.

During the internship, Charlotte said she improved her programming and increased her experience with circuits and sensors, while Andrew learned how to better manage his time through deadlines and clear objectives. Both were grateful for the hands-on experience contributing to an impactful project.

“The best parts were working with a great team, contributing to the capsule project, and seeing everything come together before my eyes,” Charlotte said. “I also liked being involved in other lab projects and learning from them.”

“I have greater confidence in my ability to engineer,” Andrew said. “Dr. Ghodssi said on our first day that we'll surprise ourselves with what we're able to achieve, and I agree wholeheartedly, as I have done work I previously believed would not be possible without further training.”

Assess and Adapt

MATRIX Lab Intern Nate works on radar detection of wood damage project in the MATRIX Lab Project Assembly Area

When Nate ran into challenges during his project, he kept his objective attainable by reframing his technical goals.

While determining the feasibility of using Ground Penetrating Radar (GPR) systems to identify the category and severity of internal damage in wood frame structures, he faced a few setbacks – first a delay in acquiring his first piece of technology, then the realization that it was not fitting for the project. He used it as an opportunity to adapt and find a new piece of technology and switched his focus to developing the sensing technology instead of the machine learning model. From there, he was able to gather the exact data he needed. Future researchers can build on his project by further refining data analysis and applying his sensing technology to field applications.

Nate says his internship improved his coding, electrical work, and mechanical design, but he also learned a lot about communication, planning, and big-picture thinking.

“The biggest takeaway I have from the internship regarding real world research is, to quote my mentor Dr. Short, ‘everything takes longer than it takes,’” Nate said. “There will always be complications you can't foresee, and it pays to be as methodical as possible instead of rushing through things with assumptions.”

Fluid Dynamics and Flexibility

University of Maryland Intern Harsha works on unmanned underwater vehicle project in the MATRIX Lab water tunnel

In the MATRIX Lab’s Hydrology Lab, Harsha contributed to a College Park research project. She worked with Dr. Cecilia Huertas Cerdeira, an Assistant Professor in UMD’s Department of Mechanical Engineering, on characterizing the performance of a tuna-inspired unmanned underwater vehicle (UUV). Harsha used the water tunnel to build and test a replica of a tuna fish’s caudal fin.

She faced some problems – including a corroded supported system and noisy data – that gave her the opportunity to find solutions. She rebuilt her setup with a less corrosive material and eliminated frequencies to ensure her data was accurate and reliable. In the future, she’ll expand her research from purely linear dynamics to nonlinear as well.

Overall, Harsha learned that research requires many different skill sets, as well as the importance of patience, planning ahead, and resource allocation.

“My research seemed purely mechanical and aerospace engineering dominant, however, throughout the process, it required plentiful electrical skills, machine work, and other interdisciplinary areas,” Harsha said. “It is vital to take this into consideration and ensure that you have ample resources to complete the project prior to beginning to make good use of time and succeed.”

Small Systems, Big Solutions

MATRIX Lab Intern Lucas works on small customized drone project in the SMART Building Electrical Engineering Lab

For Lucas, the summer was all about building tiny drones with big capabilities. His goal is to create a small, anti-jam autonomous drone with a custom flight controller and flight computer on a custom printed circuit board (PCB). His biggest issue was navigating the schedules in a professional work and research environment – waiting for help from individuals in the lab, waiting for software to be approved, and waiting for parts to arrive. He also mentioned working with small systems means problems can be difficult to notice, including mechanical issues, software bugs, and electric connections.

One of the highlights for Lucas was being able to make a drone from scratch. He said it was a joy to customize his system by adding and removing elements. He also enjoyed learning about drone flight, and looks forward to continuing to advance his project.

Aiming for Improvement

MATRIX Lab Intern Ian works on "Buoyancy-Operated roBottle" project in the MATRIX Lab Project Assembly Area

During his time at the MATRIX Lab, Ian assisted MATRIX Assistant Research Engineer Dr. Wei-Kuo Yen with the “Buoyancy-Operated roBottle” (BOB) project, which utilizes printed circuit boards and sensors to detect pressure and measure the robot's environmental conditions. He contributed by correcting some mistakes on the project's circuit board design, and added an LED to the design. He also calibrated the pressure sensor so that the BOB can collect accurate data. He worked with Dr. Yen to add epoxy to the lid as a way of making the bottle waterproof, then tested the waterproofing. He said in the future, more waterproof testing can be done to ensure moisture doesn't damage the project's components.

Ian ran into some challenges establishing a connection between radios in the apparatus. To keep making progress, he searched through the radios' datasheets and installed a driver. He also had to juggle staff schedules in order to find the time to talk about the circuit board and agree on the final design. He said making changes to the circuit board ended up being one of the highlights of his internship.

“I am a mechanical engineering student and I never had prior exposure to circuit board design, which pertains more to electrical engineering, so this was definitely a good experience for me,” Ian said. “I also enjoyed doing the waterproof testing as we did more analysis as to how to prevent water from leaking inside the bottle.”

The MATRIX Lab is proud of all the interns’ efforts bringing together human systems, engineering, and computer science to solve complex, real-world problems. Learn more about our internship positions at https://matrix.umd.edu/internship-program

Published August 8, 2025